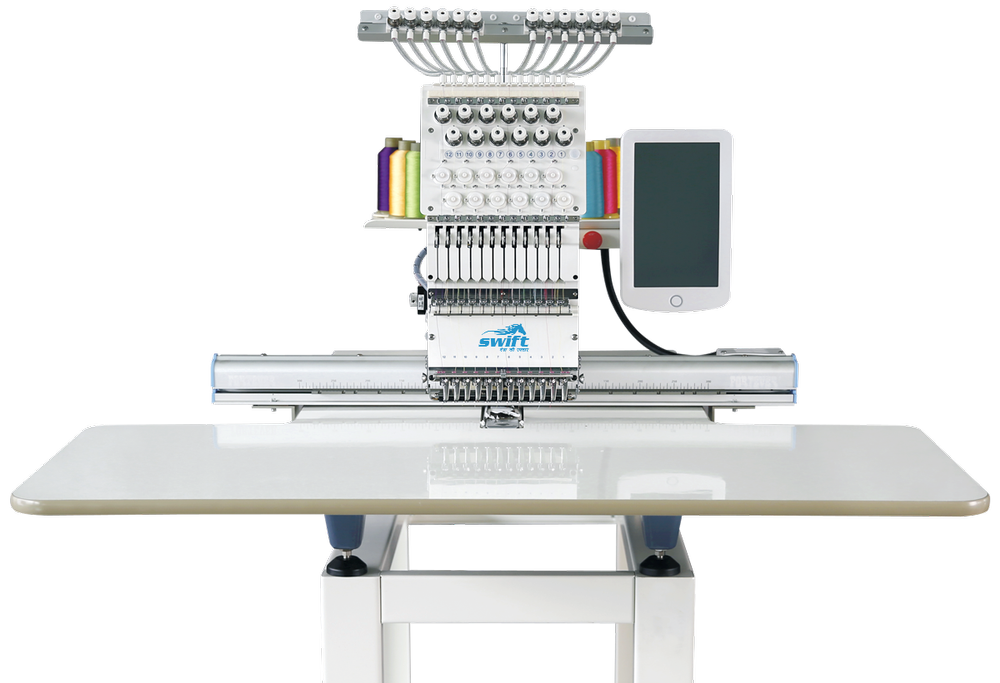

Additional Features

Suitable for embroidery on flats, caps, finished garments and more!

Perfect for small and established businesses alike

Wide angle cap system: 270°

Smaller sewing arm greatly improves the performance of cap embroidery and embroidery on small items

Heavy-duty steel stand with wheels for both stability and mobility

Multiple hoop sizes for a variety of embroidery needs

Automatic color change

Automatic thread trimmer

Reinforced upper thread clamp to ensure stable trimming

Thread break detection

Networkable and Wi-Fi capable

Design transfer via Wi-Fi from Chroma software to 10S panel

Easily add appliqué, sequin, boring or cording

Automatic memory retention

One-step tracing button on the home screen

Adjustable control panel positioning for better visibility and comfort

Recessed USB port to protect USB flash drive

Reinforced upper thread clamp to ensure stable trimming

Servo motor 150W – lowest power consumption in the industry!

Built-in universal power supply, 110V/60Hz and 220V/50Hz self-adaptable worldwide

External 100° button and trimming button

DC36V micro-step motor for X & Y axis driving ensures low noise and less vibration

Compatible with optional laser tracing device

Front LED lamp provides better visibility and protection for eyes against strong light during threading

Optional stepper motor closed-loop configuration allows the embroidery to appear more three-dimensional

Environmentally friendly packaging

Perfect for mass production of patches